In early January, Marlin magazine senior editor Sam White had a chance to tour the facilities at F&S Boatworks in Bear, Deleware. Aside from the timing (they were experiencing some of the coldest weather of the year on the East Coast that week, with a foot of snow on the ground and air temperatures in the low 20s during the day) the tour was very impressive. F&S had three boats under construction: the jig was being completed on a 75-footer that’s yet to be named; the hull had been flipped on the 61-foot Esme, and Special Situation, a 78-footer, was nearing the final stages for her anticipated delivery in April, 2017.

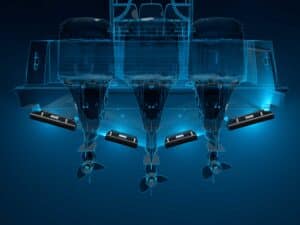

Every F&S is hand-crafted and is the result of an incredible blend of old-world craftsmanship and cutting-edge technology. The boats are built with an eye toward speed, fishability and extreme durability. The hulls feature a unique stepped design that provides an outstanding ride and excellent hull efficiency, which yields greater speed with less horsepower. Combine that with the trademark flare and tumblehome and the seakeeping abilities of a Carolina-style sport-fisher and it’s no wonder why F&S boats are famous around the world.