Tarheel is the first demo boat for Bayliss Boatworks, in Wanchese, North Carolina. She was built not only to highlight innovation, but to incorporate the input received from the captains and owners of past and present builds. Combine that with John Bayliss’ 40-plus years of experience on the water and the incredible team of craftsmen he has assembled, and this new 62 will make anyone an admirer of custom Carolina boats.

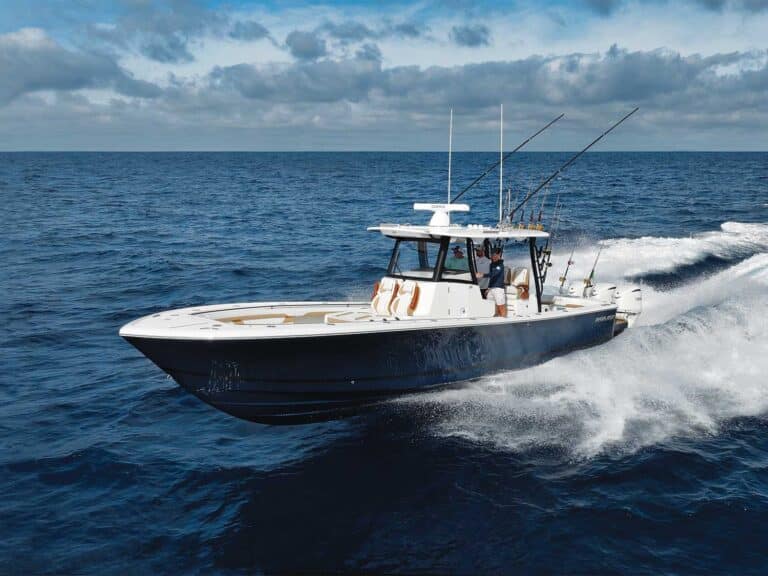

“Tarheel was designed to be an outstanding fishing boat, offering the owners and crew low maintenance and easy cleanup while maintaining the level of fit and finish people have come to expect from us,” Bayliss says. The boat lives up to her name and even sports a customized paint color—Tarheel Blue—as well as beautifully faired and curved lines. In addition, Tarheel is only the second Bayliss built without a tower and a brow mask, maintaining the focus of its design.

I was fortunate to spend a day fishing on Tarheel before the 2019 Dare County Boatbuilders Tournament, and even though the fishing was relatively slow, I could not have asked for a better day to spend on an amazing vessel with such a legendary captain and crew.

Cockpit and Bridge

The cockpit boasts a great Carolina-style transom fish box but the highlight, though, is an 11-rod rocket launcher—with a twist. Bayliss ordered the bare teak rocket launcher from Release Marine, then laminated a 1/8-inch pultruded fiberglass board to the top to prevent dings. Then the entire launcher was glassed, faired and painted in a faux teak finish.

The mezzanine is laid out efficiently, with chilled refrigerator boxes, freezer boxes and a drink box. Under each mezzanine seat is a set of customized drawers, and to port, a chilled and filtered water spigot allows the crew to refill insulated water bottles without leaving the cockpit. On the starboard side, the drawers have CNC-cut rubberized foam in the exact shape for fishing pliers, filet knives and crimping tools. There is also custom gaff storage placed neatly in the starboard corner. These unique features promote a quick find when you need items in a hurry. The engine room is accessed through the center step, allowing for very easy movement below once forward of the Seakeeper 6 gyrostabilizer.

The helm features a center console design with a Release Marine Trillion helm chair, wide seating forward with storage beneath, and two bridge wing benches. The focal point is three 19-inch displays for Tarheel‘s generous Furuno, Garmin and Simrad electronics suite. Efficiency is achieved by housing many items within a small footprint.

Interior

Entering the salon through the electric faux teak door on the boat’s centerline, the layout is spacious with ample storage throughout. The first thing I noticed was the cork flooring in the salon and galley. Cork offers a great low-maintenance alternative to wood or carpet and provides additional insulation. To port is an L-shaped sofa with cavernous customized storage. Housed behind the starboard sofa, Bayliss has created its own air-actuated, 43-inch television lift with a J.R. Beers motor and heavy-duty slide for viewing in any sea conditions. Double island counters in leathered granite accent the horizontally laid teak veneer cabinetry—which was cut from a single tree—on the forward galley bulkhead. The cooktop sits just below the granite counter, and unlike most boat-installed cooktops, the granite insert was designed with a drop slide so that it disappears under the cabinetry, negating the need to remove and store the insert. Simple and smart.

Moving forward and below, a rod and tackle storage area with a medical- grade freezer occupies the starboard companionway. The freezer is large enough to maintain a week’s worth of trolling and dredge baits, and the lid has a fiddled countertop for rigging. This same area contains a rod and reel locker and storage drawers.

Tarheel has two heads, one to port opposite the tackle area and another in the bow. Both feature showers and vanities with the same leathered granite countertops, sturdy hardware and cork flooring. The boat has three staterooms, including a forward master with port and starboard bunks. The remaining two staterooms feature stacked bunks and abundant storage throughout. The use of horizontal teak veneers continues throughout the staterooms, providing an elegant look to a boat clearly built for a traveling fishing team. A feature utilized on previous Bayliss boats is a cubby located in the wall just above each mattress for mobile devices, along with multiple charging outlets.

Engine Room

A pair of 1,920 hp MTU 12V1600M96Ls paired to Twin Disc gears powers the vessel, and twin 20-kW Northern Lights generators keep her powered up offshore. An FCI 1,850-gallon per day watermaker, tool box and ice chipper share the space; a second Seakeeper 6 gyrostabilizer is located forward on the centerline. As with all Bayliss boats, every component is mounted for easy access and the wiring is meticulously labeled.

Preserving its easy maintenance philosophy, Bayliss wanted to simplify the number of pumps and how the various components are cooled, so the team designed and built a closed-loop freshwater/glycol cooling system for all compressors, gyros and mechanical components.

This system eliminates the need for descaling or re-priming of any pumps because of rough seas or backing down hard on a fish.

“We have been developing this cooling system for a year or two, and the timing worked out perfectly to implement it on our new demo boat,” Bayliss says.

Construction and Performance

All Bayliss boats are built utilizing Okoume plywood construction for hull strength, fir for the stringers, keel, and chine logs; teak is used for the spray rails and shear guard. The hull sides are cored with Core-Cell composites between the outer triple-planked layer and inner single plywood layer. Bayliss also added a second running strake to Tarheel, which pushes the water farther aft past the house for an even drier ride.

On this boat, Bayliss utilizes faux teak in areas such as the helm pod, toe rail, drip molding and salon door to provide a lower-maintenance option, while natural teak is used for the cockpit sole and covering boards. Ultimately, the construction process provides the owner with a boat that will require less upkeep and shorter stays in the boatyard.

We discuss the future of boatbuilding with John Bayliss.

As we made our way through the Oregon Inlet, a 4- to 5-foot southwest swell and a 10- to 15-knot northeast wind made the ocean a virtual washing machine. We ran northeast cruising comfortably at 36 knots, burning just a little less than 60 gallons per side. She’s capable of cruising up to 42.5 knots, with a top speed of 48.1 knots.

The goal to refine each boat to be better than the previous one has been met in Tarheel. I can only imagine what Bayliss and his team will dream up for future builds.

| LOA: | 62’8″ |

| Beam: | 18’2″ |

| Draft: | 4’8″ |

| Displ.: | 83,000 lb. |

| Fuel: | 1,850 gal. |

| Water: | 300 gal. |

| Power: | Twin 1,920 hp MTU M96L 12V |

| Gears/Ratio: | Twin Disc/2:1 |

| Props: | Veem—34 dia. 53.5 pitch |

| Paint: | Topsides-Imron/Antifouling-Pettit |

| Climate Control: | Dometic |