I met Tim Winter and Capt. Rocky Hardison in Morehead City, North Carolina, as Winter was finishing up the last details prior to delivering Wolverine, his newest 60-footer, to the Fletcher family, and before it made its public debut at the Palm Beach Boat Show in March.

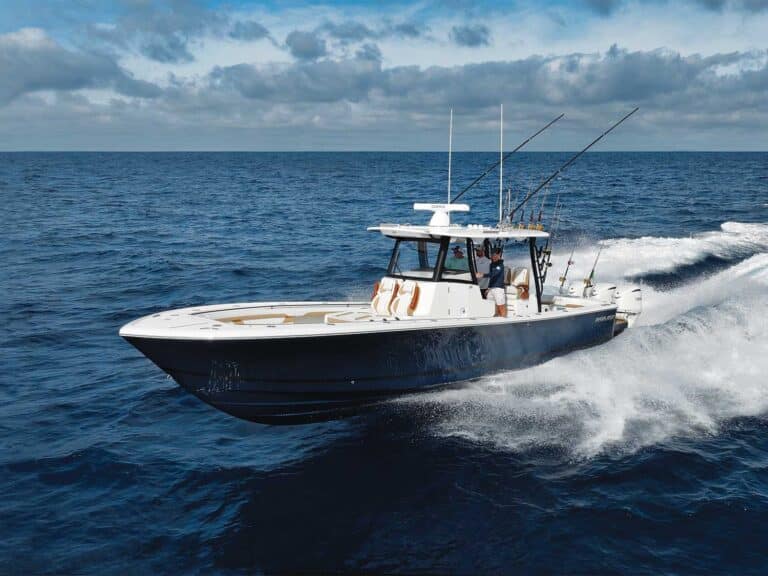

Wolverine’s curved transom, flowing broken shear line accentuated by her intermediate bumper, and beautiful Carolina flare met my expectations the moment I stepped on the dock. The sight of Hull No. 22 from Winter Custom Yachts triggered the special place in my heart for custom Carolina boats. I had watched the progress of the build for the past few months and eagerly awaited stepping aboard the beautiful rig to see what Winter had done with his latest creation.

Specs:

LOA: 60’6″ | Beam: 18’3″ | Draft: 5′ | Disp.: 79,500 lb. | Fuel: 1,925 gal.

Water: 250 gal. | Power: Twin Caterpillar C32 ACERT 1,700 hp diesels

“We built Wolverine to be a traveling boat as well as a family boat. They will fish tournaments as a family, and it’s not important to them whether they win or lose, as long as they’re all spending time together,” says Winter. “Wolverine will spend time in the Bahamas, and then fish the tournaments in North Carolina and Bermuda. She will head for the Pacific next year. The Fletchers wanted a boat capable of extensive travel with extra fuel, the ability to fish for multiple species, and all the amenities of home so they can live aboard.”

Cockpit

Wolverine’s cockpit is built to allow the family to have plenty of room to fish and have a good time together. A Release Marine chair with a massive eight-hole rocket launcher and tray is the centerpiece of the cockpit. Winter is a man of details: He placed tuna tubes on both the port and starboard gunwales with lids that are a positive fit into the tuna tubes. This simple design element will eliminate rattling and movement while underway. There are also tuna tubes on the transom within the combination livewell/fish box. The mezzanine is complete with gaff, mop and chamois storage below the seat, and also features cockpit freezers on both sides. There is additional storage, including a teak tackle locker to starboard under the overhang. The ice maker dumps into an upper compartment beneath the seat and flows down into a lower box within the step.

Accommodations

Upon entering the spacious salon through the teak sliding door, you immediately notice the beautiful teak veneer work, which was cut from the same log to produce a consistent grain throughout the living areas. A flat-screen TV is tucked inside a teak cabinet to starboard. The aft end of the cabinet contains a storage area for cameras, and is heated by the engine room to minimize lens fogging when traversing from the cool salon to the cockpit on a hot day. Built into the forward end of the cabinet is a comfortable bucket jump seat facing the L-shaped sofa to port. A raised settee sits forward on the starboard side. Below the settee are two drawers that can house an assortment of lures and teasers.

The galley is forward to port and features a pair of Sub-Zero refrigerator/freezer combos. A Keurig coffee maker rises up from under the countertop to utilize space that is typically wasted. A cooktop sits forward, along with a microwave in the forward cabinets; the upper cabinets contain custom CNC-cut dividers for cookware and pantry items.

The three staterooms below are accessed by a stairway: To port is the master with a queen bed and an accompanying bath with full-size shower. Moving forward is an over/under berth that is full of storage for rods, clothing and linens, and the day head is just aft. A tackle/rod storage closet sits between the laundry closet and the starboard bunkroom with three bunks. Typically, bunks fold up to allow access to storage, but Winter designed drawers onto the face of the bunks to make accessing this usable space easier. Winter incorporated another unique feature that affords an extra bunk: One of the lower bunks extends below the stairwell to create an additional sleeping area.

Engine Room

The Seakeeper 16 is located directly below the access to the engine room from the mezzanine. Wolverine’s engine room is spacious, allowing ample room to access the outside of the engines. All wiring is concealed behind accessible panels, creating a clean, visually appealing snow-white engine room. The dual 21.5 kW Caterpillar generators are aft of the engines and are easily accessed, just like the rest of the systems on board.

Bridge

The helm console sits port to center with a faux-teak electronics console, pod and dash. Winter typically mounts the electronics under a door, but Wolverine has three Simrad MO19-T monitors mounted to a black acrylic background with two rows of Bocatech switches for pumps and lights, producing a sleek array of electronics. A lid to port of the helm pod houses the Simrad autopilot, trim tabs, FLIR camera and the VHF command mics. Two Release Marine helm chairs sit behind the helm, and bench seating is forward of the console and on the starboard side of the bridge. A freezer under the forward bench can accommodate plenty of bait or food for when the boat is traveling. Other handy features include an air compressor to fill polyballs, as well as a separate washdown for cleaning the bridge after a long day of fishing.

Construction

Boatbuilding methods have advanced in recent years, but many builders continue to utilize plywood hulls. Wolverine is no exception, incorporating a triple-plank fir bottom and fir stringers. The remainder of the boat is constructed from Diab closed-cell foam to create a strong and light structure, and all of the hatches and hatch gutters are molded fiberglass. All areas of the boat are ventilated with forced air; Winter also utilizes an Arid dry-vacuum system to keep all bilge areas completely dry.

Performance

A pair of 1,700 hp Caterpillar C32 ACERT engines matched with ZF gears turns the set of Veem propellers to provide the power for Wolverine.

As we approached Beaufort Inlet, Capt. Hardison eased the throttles forward, and she quickly raised out of the water and accelerated with no bow lift. She settled into her cruising speed of 31-plus knots at 1,900 rpm while burning 118 gph; wide open, Wolverine makes 42 knots at 2,360 rpm with a fuel burn of 180 gph.

It was a calm day, so we were unable to observe how she handles in rough water. However, as any Winter owner will attest, the boat will exceed your expectations in any sea condition.

“Wolverine is a culmination of all I have learned in the previous 21 boats, and I could not be prouder,” said Winter as we returned to the dock. In the custom-boatbuilding arena, Winter is proving to be a hard worker with a talented team of craftsmen seeking to learn and make each boat better than the last.