Mark Willis is a detail guy. He knows and loves his boats inside and out, and nothing, no matter how miniscule, escapes his attention. For instance, I was amazed to find a plastic tip covering the sharp end of every hose clamp on his newest offering. I’d never seen that done before, and I would have escaped a lot of minor cuts and scratches over the years if someone came up with that idea sooner.

The Willis 76 Big Dog is drop-dead gorgeous, including places you can’t even see under normal circumstances. Take a peek in the aft lazarette and you’ll find that even the hydraulic lines to the rudders are made from polished stainless steel. And you won’t find common old hose in any of the fuel, water or hydraulic lines. Willis custom-fabricates all of these lines from polished stainless-steel tubing, and every inch gleams like a mirror.

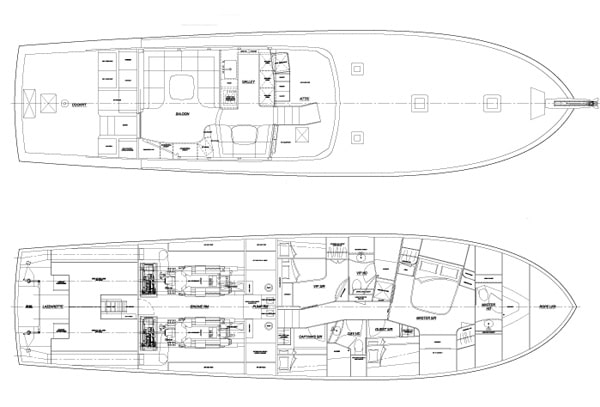

The engine room, lazarette, forward bilge, pump room and inside of the bridge console are all easily accessible and sparkling – not just spotlessly clean, but shining and polished. The paint job inside the bilge shines just like the exterior.

Willis uses a five-axis CNC router to custom-build a variety of parts, including engine mounts cut from billet aluminum to custom rod holders under the flying-bridge seats cut from starboard. I especially liked the custom mounts made for the Raycor fuel filters that slid out from underneath the engine manifolds to allow easy fuel-filter changes. With triple filters plumbed to facilitate filter changes on the run, Willis makes maintenance easy.

The electronics setup is stunning, and Big Dog’s skipper Mark Pagano made my head swim as he showed me rows of Crestron servers and three Kaleidescape DVD libraries, each holding the equivalent of 750 DVDs. Willis mounts all of these units on custom brackets made of black starboard that swivel or slide, as necessary, to allow access to the hidden units. There is even a dedicated air conditioner to cope with heat from the audio/visual system!

Willis likes to build boats that push available technology to the limits. Duplicate air compressors make sure that all of the air-activated lifters and openers keep working no matter what, including the ones on the VIP stateroom folding bed, the master stateroom bunk (accessing storage underneath), the salon door, the engine-room door and the washer/dryer door.

Even though this boat sports a lot of high-tech gadgets, Big Dog was built to fish. I could easily see both the foredeck and the fighting chair from the raised helm deck on the flying bridge. Anglers can easily clear the corners with their rod tip when using the offset-stanchion fighting chair.

Capt. Pagano, an accomplished bluefin tuna skipper, let me put her through her paces during our sea trial. I can promise you, fighting a full-grown bluefin tuna or grander marlin will not be a problem on this nimble craft.

During fish-fighting simulations, Big Dog’s controls experienced a small lag time, but that’s to be expected on today’s big boats due to emission controls. However, the boat’s 2.5:1 reduction gear and powerful 25 hp bow thruster allows her to maneuver better than most boats this size. She can also cruise and run wide-open throttle with the best of them, especially in a choppy sea.

With a Willis boat, if you can think of a custom feature you desire, Willis will most likely improve upon your idea and build it even better and prettier than you dreamed. Willis represents the art of custom boatbuilding at its finest.

Specifications

LOA……76′

BEAM……20′

DRAFT……5’6″

WEIGHT……135,000 pounds

FUEL……3,200 gallons

WATER……550 gallons

POWER……T 2,400 hp MTU M93 6V2000 diesels

PRICE……On request

Willis Marine Inc. / Stuart, Florida / 772-283-7189 / www.willismarineinc.com