My first boat was an Owens cabin cruiser, built in the early 1960s, about 30 feet long and powered by a single gasoline engine. Back then I thought it was the end all, be all — at least until I tried to anchor up on a snotty day and got the flukes of my Danforth stuck in the portside bow area of the old plywood hull, while Sea Hawk bobbed up and down like a proverbial cork on the choppy seas.

At the time, I knew nothing about boat construction or design, why the hull moved through the water the way it did — rather ungainly, if I remember correctly — and most important to me at the time, why I never was able to catch many fish on my limited forays into the open ocean.

Fast-forward these many years, and how things have changed. Boat design and construction has evolved into a high-tech arena of powerful computer programs, space-age materials and incredibly powerful engines, all in the hands of visionary and often daring marine architects and boatbuilders. The result is a broad range of high-performance state-of-the-art battlewagons that are capable of global fishing adventures.

Chines and the Center of Gravity

A recurring theme in hull design is the search for the marine equivalent of the sweet spot: the ability to move a boat through the water in the most efficient manner across varied sea conditions. This hinges on a delicate and precise balance of horsepower, hull design, weight, and where and how to put all the thousands of parts and equipment in the hull so it will be in harmony with everything else that goes into building a boat.

“My typical approach to a project is to first consider the proposed boat’s length and beam, the accommodations and machinery spaces — especially the size and horsepower of the engines in terms of the boat’s range and fuel needs — and then all that gets tweaked into the hull design,” says marine architect Erwin Gerards, whose very extensive portfolio includes projects with Rybovich, Gamefisherman, Willis, Maverick, Garlington, Release and many other top builders.

Based on these initial considerations, Gerards will then lay out the shape and design of the chine — the part of the hull where the bottom and sides meet; a boat can be said to have hard or soft chines by the measure of the interior angle formed where the bilge becomes the topsides — using a sophisticated 3D CAD program. A hard chine will have less of an angle than a soft one, and can affect stability, speed, tracking, turning and ride comfort in various sea conditions.

A critical factor is finding the all-important center of gravity, and that is the holy grail of achieving the optimal balance that any boat will have. “Simply put, this is the weight of the entire boat pushing down against the hydrodynamic forces, those physical principles acting upon an object moving through the water,” Gerards explains. “With planing hulls, you always want the CG to be aft of the point pushing the boat up or otherwise you’re going to be running bow down. Conversely, of course, you don’t want to have your boat’s transom squatting while running, either.” Not having this initial — and essential — part of the design in place will result in an inefficient hull and a boat that just doesn’t take to the water too well.

In addition to the CG, the actual shape of the chine will dictate where the hydro-dynamic pressure points are located that will act to push up the bow. “Based on that position, I can accurately target the best place to fill the engine space, arrange the fuel tanks, all the pumps and the generator, along with the other necessary equipment for this particular vessel’s operating profile,” Gerards notes. “Balance results in optimal efficiency.”

Balancing the Build

On the topic of fuel tanks, Gerards prefers to have the boat’s aft tanks supplemented by one located forward of the engine room. This way, as the boat trims while burning off fuel, the additional tankage will deliver gravity-fed or pumped fuel for a more even trim without having to use tabs. “It looks better for the boot stripe as well,” he adds.

Another important factor in finding harmony and balance in design and engineering is considering the new, more-powerful engines that are available in today’s market. While we may have maxed out the horsepower for now, having this kind of power on hand does come with several caveats.

“The first consideration is weight, a prime concern when trying to determine the best design for any boat,” Gerards begins. While the higher-horsepower engines are able to push 70- and 80-plus-foot boats at higher speeds, they also need larger tanks to hold the extra fuel, more space for bigger exhausts and air intakes, and more-robust running gear, all at the expense of cost and efficiency. And of course, putting a too-large engine in a smaller boat is not a very good idea either. “It is much more effective to go down in horsepower in a 60- or 65-footer, for example, and move the boat with less fuel while still getting good performance,” Gerards says. “Gaining 1 or 2 knots at the upper end with more horsepower is just not that important.”

When it comes to the running bottom, keeping weight down is a prime concern as well. When the hull design is directly connected to a study of how heavy things get, and the resulting effect on the hydrodynamic calculations — trust me here, and without getting into deep physics equations, this is very important — the information is passed on from the marine architect to the builder, and the entire process going forward is based on this data.

Computer-Aided Design Comes of Age

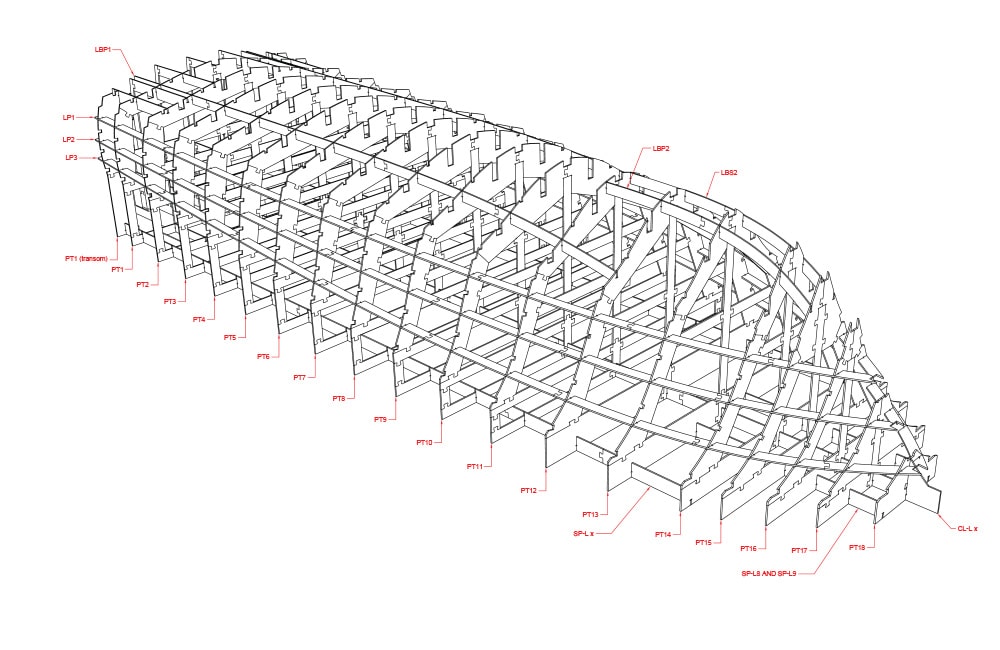

An additional area that has contributed to more-efficient and better-performing boat designs is a result of some very highly sophisticated computer programs. “With cold-molded builds, and prior to CAD, we would loft the body plan on the floor, then transfer it to plywood and set up the jig at that point,” Gerards says.

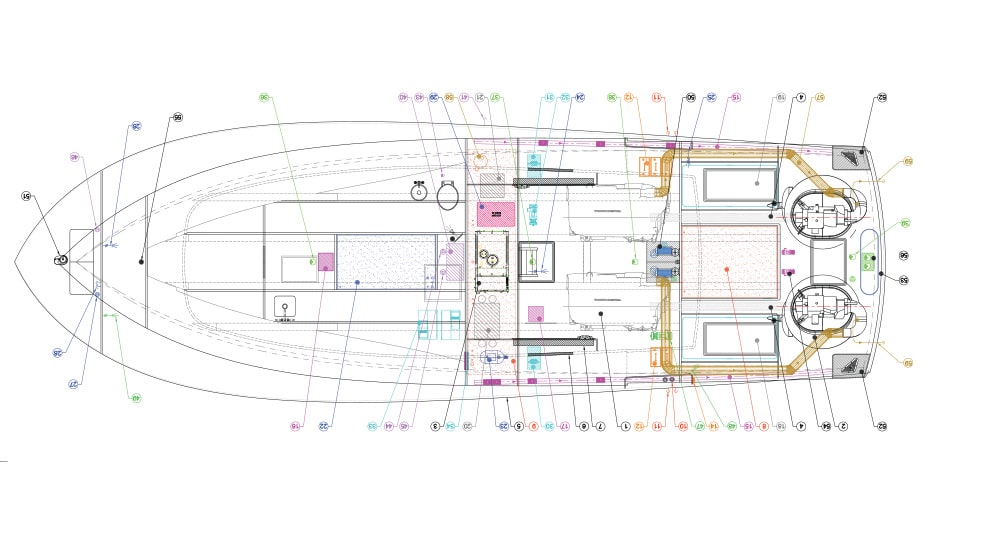

With CAD, you can get everything in 3D modeling: Every part of the boat that goes into the build, including all the plumbing and wiring, is included. This also serves to define the sections for building the jig. “In the custom sector, not only is this cost-effective, but with the precision of the program, the result is a better build,” he adds.

Because the weight factor is so important, and that its total will be based on the CG location for a particular design, another big plus with the CAD program involves computational fluid dynamics. While it’s a mouthful, and with enough high-level explanations to make your eyes glaze over, this calculation basically tells you how the boat is going to run. “It dials into the shape of the boat’s bottom and, unless you are really going out on a limb, trying to do something that pushes the design envelope, this is helpful,” Gerards says. “Doing this kind of research by hand is a thing of the past. Changes nowadays are done as easily as a keystroke, and are quite exact.”

Individual Attention

“The way we approach a project with the sport-fish sector is to work closely with the builder,” says Chris Swanhart, project manager at Donald L. Blount & Associates — whose work has included builds with Jim Smith Tournament Boats, Weaver Boat Works and Bayliss Boatworks — among many other notable builders. “The level of work will differ with each individual job we take on.”

If the builder — in the case of Jim Smith, for example — supplies the general arrangement plan of the boat, Swanhart will start with the naval architecture, engineering, weight estimating, and performance and power needs, among many other factors. Analyzing that information results in drawing the hull form. “On the other hand, with a client like Weaver Boat Works, we have also been a little more involved in helping develop the profile and other items, always keeping in mind that it has to be in line with the particular style of that builder.”

Since each builder’s needs are different, Swanhart and the DLBA team will make sure the hull form, shear line, and particular design cues like the deck, house, flybridge, and window line are all taken into account in the preliminary drawings. Once this phase is reached and there is agreement all around, the exacting work on the hull form and lines, weight, and props comes next. “Any design has to meet two important criteria: the aesthetic needs of the builder and the owner, and our technical requirements for a high-speed sport-fish hull,” notes Swanhart.

“We always say that the yacht must look terrific, but she’s got to run even better.” —Chris Swanhart, DLBA

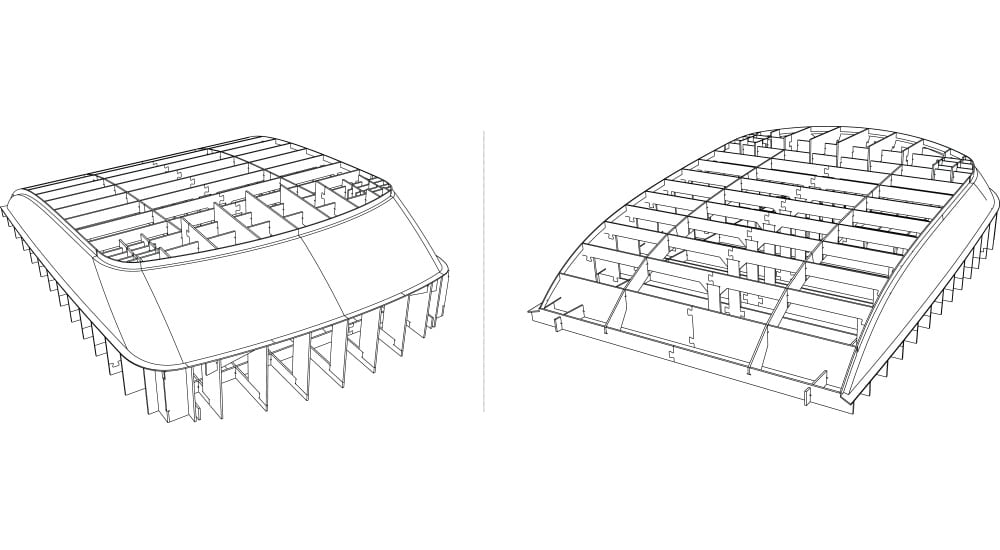

Working with Bayliss Boatworks also came to mind for Swanhart. “We have been heavily invested right from the beginning, during the conceptual phase,” he says. “That resulted in doing a lot more with John and his team at Bayliss.” Regardless of the builder, the delivered package includes the hull form and jig frames with which to build the boat. Jig-frame kits can also include the deck, house and bridge. The latest jig kits go together like a giant 3D puzzle, making it easier for the builder to assemble.

Balancing Weight and Performance

With performance being an important aspect, with speeds in the 40-plus-knot range — and some even tickling 50 knots these days — all the hulls are hard-chined. “There are many kinds of variables that go into hull development, and we have an exacting criteria we always have to meet for performance,” Swanhart says.

Regardless of each build, the critical component is always the weight estimate: a fairly exact itemization of what’s in the boat and where, and the location of the center of gravity. How important? Any deviation from this estimate can affect dynamic stability. “Our weight designs take into consideration all types of conditions, fuel use and other factors to avoid with the hull shape; for example, getting squirrely in a following sea. The boat should run as expected,” Swanhart says.

When it comes to the higher-horsepower engines, as well as today’s seemingly standard option — a gyrostabilizer — Swanhart had some additional thoughts. “Large boats, 70 feet and up, are commonplace now,” he reports. “So with the design variables known, we can design a hull that optimizes speed, handling and ride quality. We have several designs on the water that are north of 80 feet and exceed 45 knots.” As far as the gyros go, Swanhart notes that while retrofits present not only location problems but weight distribution issues as well, most if not all boats being designed today have dedicated spaces for this equipment, along with the weight already figured into the equation.

With refits, the real challenge lies when a boat has a pair of 1,600-horsepower engines and the owner wants to bump up to a new 2,000-horsepower set. While the new power plants are not that much heavier, the boat will have a tendency to behave a bit differently with the new speed ceiling. “There can be issues with going from 12-valve to 16-valve engines in a repower,” Swanhart says.

DLBA uses parametric software, specifically designed for its hull applications. Given its properties, Swanhart can tweak things on the fly. “When I want to make a change, I don’t have to start over,” he points out. “I can just go into a small hull feature I need to modify or improve upon, and the 3D modeling of the CAD program allows me to see critical areas such as space allocation. We can figure out any problems before they happen on the builder’s shop floor.”

The Craftsmen

Along with the naval architects, I was also able to get insight on this topic from several builders as well. “When I started building boats some 31 years ago now, we were all experimenting with the full-keel boat design some of the guys were using in the lower Outer Banks,” says Jarrett Bay’s Randy Ramsey. Those changes included altering the shape of the hull in order for the boat to get up on plane easier. Plug in higher-horsepower engines and the need for a modified-V hull, similar to that of the World War II-era PT boats that could carry a sharp entry forward through the engine room and flatten out aft, began to take hold. “This design also allowed us to better deal with head-to or quartering seas,” he says. But too sharp and not full enough, and a boat would not do well before the sea; conversely, too full and the hull would pound. Again, it’s no small matter finding that optimal balance. “Working with our design and naval-architect team ensures that we are spot-on in our final product — no matter what size — where the center of gravity is in the proper place so the boats will float correctly and perform well,” Ramsey says.

“As we go through the years, we try to improve our hull design with each model,” says Gary Davis, Jarrett Bay’s third-generation boatbuilder. Along with product engineer Chad Voorhees and naval architect Brandon Davis, they are the team responsible for the striking design features and performance found in this custom builder’s line.

Ramsey, Davis and the Jarrett Bay team rely on, among the many other important aspects of their builds, weight and moment — that being how little it takes to have a negative effect on the bow, stern and even the centerline. “We’ve come a long way these days, trying to maintain speeds while working with weight savings anywhere we can,” Davis says.

The Power to Perform

A real game-changer came several years back when Jarrett Bay teamed up with MTU on its 4000 Series diesel engines. “We learned a lot with that experience — not only working with big power, but with running gear and fuel placement as well,” Davis says. “The result on our hull designs was a minor tweak here and there, and we found we were exactly right with deadrise, water flow, performance and efficiency. While each boat is different, from our 50-footers to our 70-footers, it enabled us to be more consistent from boat to boat,” notes Davis. “With this new 90-footer we’re building, the owner wants to go as fast as he can, and with the current big engines just about maxed out, we’ll be working with what we have to deliver a boat that can not only handle any sea condition, but also move through the water as efficiently as possible,” he added.

As with most builders, Jarrett Bay Boatworks is using lighter, stronger carbon-fiber components such as stringers and bulkheads as well as coring in the decks.

Weight constraints are extremely important in any build, but when you have limitations on horsepower, this can be one of the prime factors affecting the design of any boat. “Working with what we have, and trying to up the performance curve at the same time, has seen us put a bit more shape into our hull, with a transition to about 10 to 12 degrees by the time we get to the transom,” says Davis. “We try to get the water to flow past our hulls as straight as possible to avoid any drag.”

Dominic LaCombe at American Custom Yachts in Stuart, Florida, also chimed in with some thoughts: “Once you know what the owner wants, it becomes critical to understand what they would like inside the boat in order to have the hull perform the way it should. That’s always a compromise, and one that is a critical factor in the relationship between the design of a boat, the props, all the machinery and accommodations, equipment, fuel and water tanks, and just about anything else that can affect where water touches the hull.”

Using the all-important CAD program along with multi-axis routers, which allow scanning and prefabrication of critical parts, and precise measurements to ascertain the optimum CG, results in a spectacular build such as ACY’s 90-foot C’est La Vie. LaCombe and his team perform extensive testing to see how a hull stays in the water and how it runs while dialing in several different load scenarios, among many other tests. All this is done to discover where to put things inside the boat as well as to determine what is lifting the hull and where.

“Years ago, we had to build the boats extremely light because we had only a finite amount of available horsepower,” he says. “Now, with today’s range of power options, the boats — even some of the big ones — have become much closer in speeds,” he says. “With a keen eye on weight, which is a major, if not the biggest factor in design, a big boat can go relatively fast even with added tankage and equipment. Not only with the new engine technology, but also the advances in building materials and composites that we are working with are giving us new ways to make this happen. But when considering speed, the design has to be efficient. One cannot exist without the other.”

Moving Forward

Each of the experts agrees that the big changes in the future will come from even-more-advanced computer programs that will be able to dial in what could be the most efficient and highest-performing hulls ever seen on the water. And with advances in highly developed composites, stronger adhesives and better protective coatings, as well as new machining processes, including robotics, and a better understanding of how to improve the way in which our vessels move through the water, the future looks incredibly bright for the boats of tomorrow. We have come a long way since my first little plywood-hulled boat, and I can’t wait to see what lies ahead.

About the Author: Capt. Ken Kreisler has been an industry insider for over 25 years with such publications as Power & Motoryacht, Yachting, Marlin and Southern Boating magazines. Author of Powerboating: Your First Book for Your First Boat, he is currently at work on a nature book.