Courtesy Jarrett Bay Boatworks

|

Subscribe Now and Save 68% |

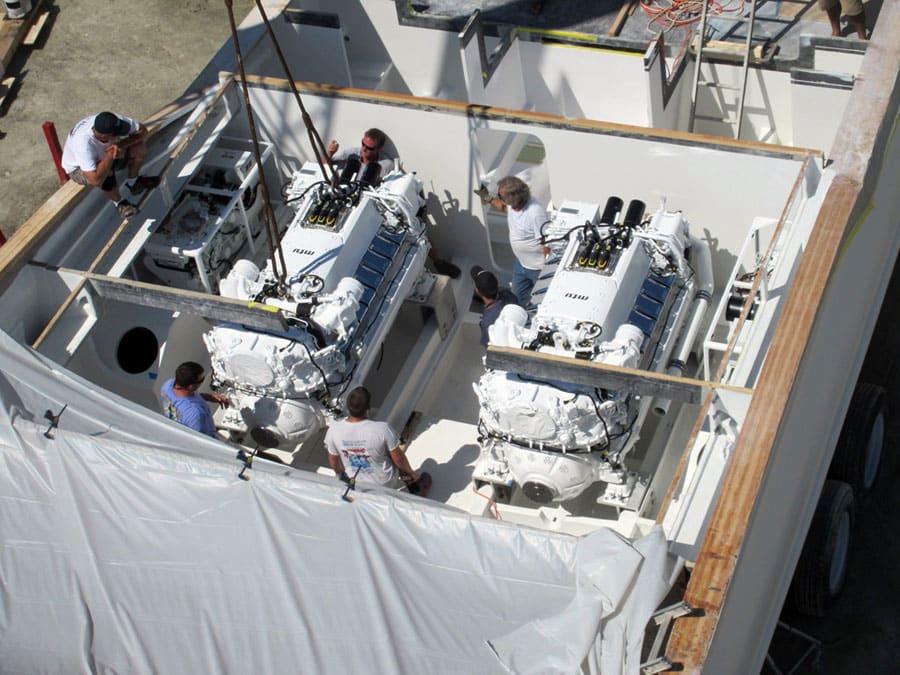

This time lapse video shows the installation of one of the two massive MTU 16V Series 2000 diesel engines on Jarrett Bay's new 90-footer, Project Ireland, which is making progress toward its scheduled spring 2017 completion.